Wire Electrical Discharge Machining (EDM) has become indispensable for manufacturers needing extreme precision, tight tolerances, and the ability to cut complex geometries in hard materials. However, if you are considering investing in a Wire EDM machine, understanding the factors that drive pricing is essential to make an informed decision and budget effectively. This article breaks down what determines Wire EDM machine costs, how to assess value, and tips to plan your investment wisely.

Why Wire EDM Machines Vary So Much in Price

Wire EDM machines range widely in price depending on their capabilities, technology, and the level of automation they offer. Entry-level machines designed for basic applications can cost significantly less than high-performance models intended for aerospace, medical device, and mold-making industries.

Consumables and accessories also factor into the total cost of ownership. For example, high-performance brass wire like Wire Edm Machine Price contributes to faster cutting speeds and better surface finishes, which can help justify a higher initial investment in machines optimized for advanced wire technology. Understanding how each element contributes to both upfront and long-term costs is key to choosing the right solution for your needs.

Major Factors That Influence Wire EDM Machine Prices

Below are the most significant variables that affect the price of a Wire EDM machine:

1. Machine Size and Work Envelope

Larger machines with bigger worktables and extended Z-axis travel can accommodate more substantial parts and thicker materials. This extra capacity increases both the physical footprint and the cost. When comparing models, consider the maximum part size you expect to process regularly.

2. Accuracy and Surface Finish Capabilities

Machines built to achieve ultra-precise tolerances (down to ±0.001 mm) and fine surface finishes command higher prices because of their more sophisticated controls, linear motors, and precision components. If your work requires demanding tolerances, this investment can be critical to maintaining quality.

3. Cutting Speed

Higher cutting speeds translate to shorter production times and increased throughput, but they require advanced power supplies and control systems. Machines optimized for speed may come at a premium but can pay off in reduced labor costs and faster project turnaround.

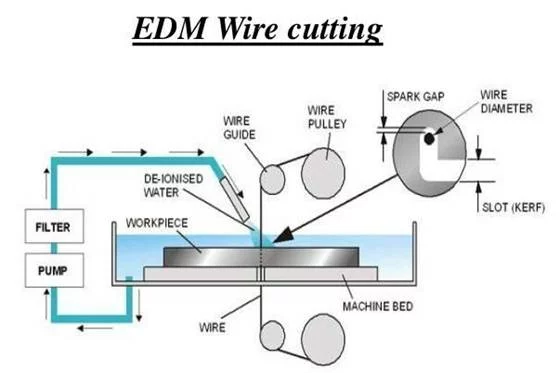

4. Wire Diameter Compatibility

Some machines can handle a broader range of wire diameters, from extremely fine wires for micro-components to thicker wires for large workpieces. This versatility affects cost but also adds flexibility for different applications.

5. Automation Features

Automated wire threading, adaptive control, and unattended operation capabilities all drive up the price but save considerable time and labor in production. Shops with limited manpower or those running multiple shifts often find these features essential.

6. Dielectric System

The design and capacity of the dielectric system also impact pricing. Larger or more advanced filtration and cooling systems enable longer continuous operation and improved cutting consistency.

7. Brand and Support

Reputable brands with established service networks and reliable spare parts availability often command a premium over lesser-known brands. While it might be tempting to choose a cheaper option, consider the value of expert technical support and easier maintenance over the lifespan of the machine.

Additional Costs to Consider

When budgeting for a Wire EDM machine, remember to account for:

- Consumables: Wire, filters, dielectric fluid, guides, and power contacts are all recurring expenses.

- Training: Operators may need specialized training to run and maintain the machine effectively.

- Installation: Moving, leveling, and setting up the equipment can be a significant cost.

- Software: CAM software licenses for programming can add to the total price.

- Maintenance Contracts: Preventive maintenance agreements help avoid unexpected downtime but come with their own fees.

Budgeting Tips for Wire EDM Investment

- Assess Current and Future Needs: Don’t overspend on capabilities you may never use, but also avoid outgrowing your equipment too soon.

- Consider Total Cost of Ownership: Calculate not just the purchase price but also the long-term cost of consumables, maintenance, and downtime.

- Explore Financing and Leasing: Many suppliers offer financing options that spread out payments and preserve working capital.

- Evaluate Used Equipment: Certified pre-owned machines can provide excellent value if properly maintained.

- Request a Demonstration: Seeing a machine in action will help you assess whether its performance justifies the price.

Conclusion

Investing in a Wire EDM machine is a strategic decision that can drive significant improvements in quality, efficiency, and capabilities. By understanding what influences machine pricing and planning for long-term operating costs, you can make a confident choice that supports your production goals. Whether you prioritize cutting speed, accuracy, automation, or all of the above, a clear understanding of your requirements will guide you toward the best investment for your business.