Efficient material handling is a critical aspect of modern industrial operations, especially in sectors such as mining, agriculture, construction, and manufacturing. One essential tool that has revolutionized the loading and unloading process is the truck loading conveyor. This equipment significantly improves productivity, reduces manual labor, and ensures the safe transfer of bulk materials from storage or production areas to transport vehicles.

A truck loading conveyor is a type of conveyor system designed specifically for transferring bulk materials, such as grains, coal, minerals, sand, or gravel, directly into trucks. Unlike stationary conveyors used for internal plant operations, these conveyors are built to accommodate mobile loading requirements and can often be adjusted in height and length to fit various truck sizes. Their primary goal is to streamline the loading process, reduce operational downtime, and minimize spillage and material loss during transportation.

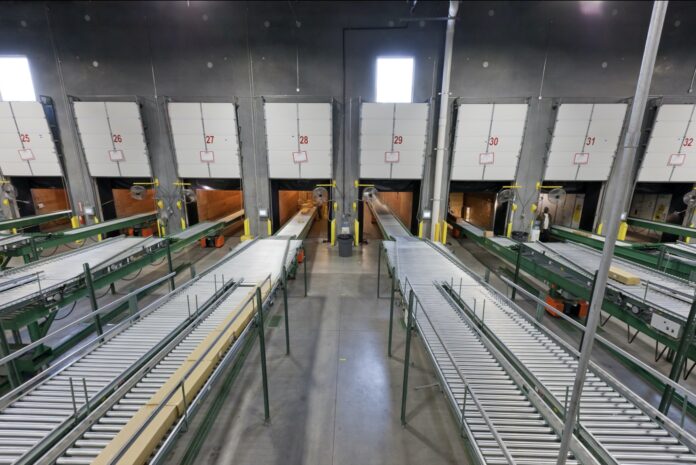

The design of truck loading conveyors varies depending on the material type and the operational environment. Commonly, they consist of a belt system mounted on a robust frame, powered by electric or diesel motors. The belt moves continuously, carrying the material from the feed point to the discharge end, where it is deposited into the truck. Many systems include adjustable chutes or telescopic sections, allowing operators to position the material accurately, reducing waste and ensuring even distribution within the truck bed. For a closer look at options and models, you can explore Truck Loading Conveyor solutions that offer flexibility and efficiency in industrial loading operations.

Key Components of a Truck Loading Conveyor

Understanding how a truck loading conveyor works requires familiarity with its primary components. These conveyors typically include the following elements:

- Conveyor Belt: The belt is the central part of the system, responsible for carrying materials from one point to another. Belts are usually made from durable rubber, PVC, or synthetic materials to handle different weights and abrasiveness levels.

- Drive System: The motor and gearbox combination powers the conveyor belt. Depending on operational needs, these can be electric, hydraulic, or diesel-driven.

- Frame and Structure: The frame provides support and stability to the entire conveyor. Some frames are fixed, while others are portable or telescopic to accommodate different truck heights and loading positions.

- Idlers and Rollers: These components reduce friction and support the belt, ensuring smooth material movement.

- Discharge Chute: This section directs the material from the belt into the truck, often adjustable to control flow and placement.

- Control System: Modern conveyors often include automation options for speed control, start/stop functions, and emergency stops to enhance operational safety and efficiency.

How a Truck Loading Conveyor Works

The operation of a truck loading conveyor is straightforward yet highly effective. Materials are first loaded onto the conveyor belt from a hopper, silo, or other storage units. Once the belt is activated, it carries the material along its length toward the discharge end. At the discharge point, the material is guided into the truck bed through a chute or an adjustable telescopic section, which ensures precise placement and reduces spillage.

The ability to adjust the height and angle of the conveyor is a crucial feature. Operators can position the conveyor to match the truck’s dimensions, allowing for uniform distribution of the load. This not only maximizes truck capacity but also prevents overloading on one side, which could cause imbalance and potential safety hazards during transport.

Some advanced truck loading conveyors are equipped with sensors and automation features. These systems can monitor the truck’s fill level and automatically stop the conveyor when the desired load is reached. This automation enhances efficiency, reduces labor requirements, and prevents wasteful overfilling. Additionally, safety features such as emergency stop buttons, belt misalignment detection, and protective covers help minimize accidents and equipment damage.

Advantages of Using Truck Loading Conveyors

The use of truck loading conveyors offers several significant benefits to industries that handle bulk materials:

- Increased Efficiency: Conveyors can move large quantities of materials quickly and continuously, reducing loading time compared to manual methods.

- Reduced Labor Costs: Automation and mechanization mean fewer workers are required for the loading process, which cuts operational expenses.

- Enhanced Safety: By minimizing manual handling, conveyors reduce the risk of injuries caused by lifting heavy materials or exposure to dust and debris.

- Material Handling Precision: Adjustable chutes and telescopic sections ensure accurate material placement, reducing spillage and maximizing truck capacity.

- Scalability: Truck loading conveyors can be customized in length, height, and capacity, making them adaptable to various materials and operational requirements.

Applications of Truck Loading Conveyors

Truck loading conveyors are versatile and find applications across multiple industries:

- Mining: For loading coal, ores, and aggregates into trucks for transport to processing facilities.

- Agriculture: For efficiently transferring grains, seeds, and fertilizers into trucks or trailers.

- Construction: For sand, gravel, and cement distribution at construction sites.

- Food Processing: For bulk loading of grains, sugar, and other food products into delivery trucks.

- Waste Management: For transporting recyclable materials or waste to disposal or processing sites.

Conclusion

A truck loading conveyor is an indispensable tool in modern bulk material handling. By automating the loading process, it enhances productivity, ensures safety, and reduces operational costs. Its adjustable features, durable construction, and automation capabilities make it suitable for a wide range of industries. Investing in a reliable truck loading conveyor system is a strategic choice for businesses looking to streamline operations and achieve efficient, precise, and safe material handling.