Proper chemical handling is critical in laboratories, industrial plants, and manufacturing facilities. Many processes involve acidic or alkaline substances that, if not carefully monitored, can pose safety hazards to personnel, equipment, and the environment. One of the most effective tools for maintaining safe chemical operations is the pH sensor, which allows real-time monitoring of solution acidity and alkalinity to prevent dangerous conditions.

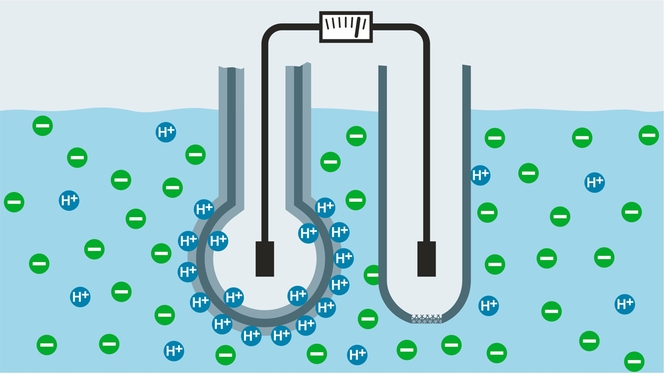

pH sensors measure the concentration of hydrogen ions in a solution and convert this data into an electrical signal, providing precise readings of pH levels. This real-time feedback is essential in chemical handling, as it allows operators to respond immediately to deviations. For an in-depth explanation of how these sensors function and their applications, you can explore this guide on pH sensors, which covers the technology and principles behind these devices.

The Safety Risks of Improper pH Monitoring

Incorrect pH levels in chemical processes can lead to a variety of hazards. Highly acidic or alkaline solutions can cause burns, damage equipment, or trigger unwanted chemical reactions. In industrial settings, uncontrolled pH fluctuations can result in explosions, toxic gas release, or contamination of products. Even minor deviations can compromise safety in laboratories and manufacturing facilities. Continuous monitoring with pH sensors helps mitigate these risks by providing accurate, real-time data for immediate corrective actions.

How pH Sensors Enhance Safety

pH sensors improve safety in chemical handling in several ways:

- Real-Time Alerts: Sensors provide continuous monitoring, alerting operators when pH levels move outside safe ranges. This allows rapid intervention before hazardous conditions escalate.

- Accurate Measurement: Precise readings reduce human error associated with manual testing methods, which can sometimes be slow or subjective.

- Automation Integration: Many sensors can be connected to automated control systems that adjust chemical additions or shut down processes if pH thresholds are exceeded, preventing accidents.

- Durability in Harsh Conditions: Sensors designed to withstand corrosive chemicals ensure reliable performance even in aggressive environments, minimizing the risk of sensor failure leading to unsafe conditions.

By combining accurate measurement with automated response capabilities, pH sensors create a safer working environment in facilities that handle reactive or hazardous chemicals.

Types of pH Sensors Used in Chemical Safety

Different chemical processes require sensors that are tailored to the environment and solution types:

- Glass Electrode Sensors: Offer high accuracy and are suitable for most aqueous solutions.

- ISFET Sensors: Solid-state devices that provide rapid response and can endure harsh or high-temperature conditions.

- Combination Electrodes: Integrate both the measuring and reference electrodes, simplifying installation and maintenance while providing reliable readings.

Choosing the correct type of sensor ensures consistent safety monitoring and reduces the likelihood of equipment or human exposure to harmful conditions.

Calibration and Maintenance

Accurate pH readings depend on regular calibration and maintenance of pH sensors. Calibration is usually performed with standard buffer solutions to correct for drift caused by electrode aging, fouling, or temperature changes. Maintenance includes cleaning electrodes, checking reference solutions, and replacing worn components. Properly calibrated and maintained sensors ensure reliable monitoring, which is essential for safety in chemical handling.

Applications Across Industries

pH sensors are employed in a wide range of industries to enhance safety:

- Chemical Manufacturing: Ensuring controlled reactions and preventing accidental releases of hazardous substances.

- Pharmaceutical Production: Monitoring solution pH during formulation to prevent unsafe deviations.

- Water Treatment Facilities: Controlling chemical dosing to avoid harmful levels of acids or bases.

- Laboratory Settings: Maintaining safe handling conditions for research chemicals and reactive solutions.

In all these applications, accurate pH monitoring reduces the risk of accidents and supports compliance with occupational health and safety regulations.

Conclusion

The use of pH sensors is a vital safety measure in chemical handling. By providing accurate, real-time monitoring of solution acidity and alkalinity, these devices help prevent accidents, protect personnel, and maintain equipment integrity. Proper sensor selection, calibration, and maintenance enhance performance and reliability, making pH sensors indispensable in laboratories, industrial plants, and chemical manufacturing environments. Integrating these sensors into safety protocols ensures safer operations, reduces risk, and supports a proactive approach to chemical management.