The demand for customized apparel has rapidly increased over the past few years, and the textile industry has evolved to keep up with this trend. One of the most innovative developments is the Sock Printing Machine, a specialized device designed to produce detailed, colorful, and long-lasting prints directly on socks. Whether for small-scale boutique production or large industrial operations, selecting the right machine is key to ensuring efficiency, quality, and profitability.

Understanding the Importance of Advanced Sock Printing Technology

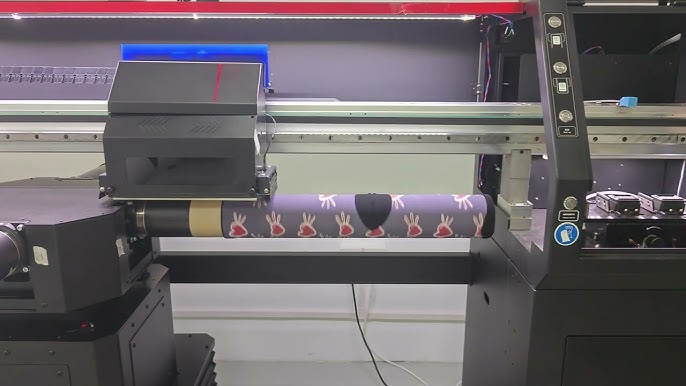

Modern sock printing has moved far beyond traditional methods like embroidery or basic screen printing. Today’s advanced machines allow manufacturers to print intricate patterns, gradients, and high-definition images directly onto fabric. These innovations have opened up new opportunities for designers to express creativity and for businesses to deliver customized products that meet diverse consumer preferences.

Investing in a quality Sock Printing Machine is not just about acquiring new equipment; it’s about improving productivity, enhancing design flexibility, and achieving consistent results that meet industry standards. The right machine can help streamline operations, reduce production time, and improve overall customer satisfaction.

1. High-Resolution Printing Capability

One of the most important features to look for in a sock printer is its printing resolution. A high-performance machine should offer exceptional clarity and precision to reproduce detailed artwork and complex patterns. Look for models that provide high DPI (dots per inch) output, as this ensures crisp and vibrant designs that maintain their quality after washing and repeated use.

2. Efficient Color Management System

A reliable color management system is crucial for achieving consistent results across multiple production runs. The best machines come equipped with advanced color calibration tools that accurately translate digital designs into printed products. This feature ensures that each pair of socks has uniform color tones, regardless of the material or design complexity.

3. Versatility in Fabric Compatibility

Different socks are made from various materials such as cotton, polyester, nylon, or blends. A top-tier sock printing machine should be compatible with multiple fabric types without compromising print quality. Machines that include adjustable settings for temperature, ink flow, and pressure offer greater flexibility for working with diverse materials and textures.

4. Speed and Productivity

Production speed is a major factor for businesses aiming to scale operations. High-performance machines are designed to handle large volumes of socks in a shorter period without sacrificing print accuracy. Automated systems, quick-drying ink technologies, and streamlined workflows help maximize output while minimizing downtime.

5. Durable and Eco-Friendly Inks

Quality printing is not just about appearance; it’s also about durability and sustainability. Choose machines that support eco-friendly inks that adhere well to fabrics and resist fading or cracking. Water-based inks are particularly popular in the industry because they are both environmentally safe and capable of producing vivid, long-lasting colors.

6. Easy-to-Use Software and Controls

User-friendly software is essential for efficient production. Modern sock printers feature intuitive design interfaces that allow operators to easily upload, adjust, and preview designs before printing. Advanced systems may also include preloaded templates, automatic alignment features, and real-time monitoring for improved precision and reduced human error.

7. Maintenance and Support Features

A high-quality Sock Printing Machine should be designed for easy maintenance. Machines with self-cleaning print heads, automated calibration, and built-in error detection can significantly reduce downtime. Additionally, reliable customer support and readily available spare parts ensure smooth operation and minimize disruptions in production.

8. Cost Efficiency and ROI

While the initial investment in a high-end sock printer may seem substantial, the long-term benefits often outweigh the cost. Efficient machines reduce material waste, lower labor costs, and speed up production times, all of which contribute to a faster return on investment.

Conclusion

Choosing the right Sock Printing Machine is a strategic decision that directly affects product quality, operational efficiency, and overall business growth. By focusing on features like high-resolution output, fabric versatility, eco-friendly ink options, and ease of maintenance, businesses can ensure they are investing in technology that delivers both performance and reliability. As the demand for customized apparel continues to rise, adopting advanced printing equipment is the key to staying competitive in the ever-evolving textile industry.