Agitated Nutsche Filter Dryers (ANFDs) are essential equipment in industries such as pharmaceuticals, chemicals, and specialty materials, offering integrated filtration, washing, and drying in a single enclosed system. Their ability to handle a wide range of materials efficiently while maintaining product quality has made them a preferred choice for modern industrial operations. For manufacturers looking to invest in high-performance equipment, understanding leading global suppliers and their offerings is crucial. These companies focus on innovation, reliability, safety, and compliance with international standards to meet the demands of various industries.

A leading Agitated Nutsche Filter Dryer Manufacturer typically offers solutions that combine advanced filtration technology with automation, safety, and durability. Such manufacturers design vessels and agitators for optimal performance, ensuring uniform cake formation, efficient washing, and rapid drying. They also provide customization options for vessel size, filter media, heating methods, and control systems, enabling clients to tailor solutions for specific materials, batch sizes, and production requirements. By integrating process efficiency, regulatory compliance, and safety features, these suppliers set the benchmark for industrial-grade ANFDs.

European Manufacturers

Europe is home to several prominent ANFD manufacturers known for engineering excellence and high-quality standards. Companies from Germany, Switzerland, and Italy have established reputations for producing reliable and innovative filtration systems. European manufacturers often focus on precision engineering, material selection, and compliance with international standards such as ASME, PED, and GMP. Many offer advanced automation features, real-time monitoring, and CIP/SIP compatibility, making them ideal for pharmaceutical and chemical applications where product purity and regulatory adherence are critical. Their strong emphasis on safety, energy efficiency, and process optimization has made European ANFDs a benchmark in the global market.

North American Manufacturers

In North America, several manufacturers have built a strong presence by combining technological innovation with robust customer support. These companies focus on producing versatile ANFDs that can handle challenging slurries, fine powders, and abrasive materials. U.S. and Canadian manufacturers often integrate advanced control systems, allowing real-time monitoring and automation of agitation, vacuum, pressure, and heating processes. North American suppliers also prioritize safety, incorporating interlocks, pressure relief devices, and inerting systems to handle hazardous materials. Many of these manufacturers have extensive experience in pharmaceutical and specialty chemical sectors, providing scalable solutions that meet strict regulatory requirements.

Asian Manufacturers

Asian manufacturers, particularly those in India, China, and Japan, have emerged as competitive players in the global ANFD market. These companies focus on providing cost-effective, high-performance filtration systems suitable for a variety of industrial applications. Many Asian suppliers offer fully automated ANFDs with programmable logic controllers (PLCs), human-machine interfaces (HMIs), and process optimization features. The combination of affordability, customization, and adherence to international quality standards has enabled Asian manufacturers to expand their presence in both domestic and international markets. Additionally, many of these suppliers emphasize research and development, producing innovative solutions for improved filtration efficiency, faster drying cycles, and reduced solvent consumption.

Key Features Offered by Leading Manufacturers

Top global ANFD manufacturers differentiate themselves through a combination of performance, safety, and versatility. Key features typically include:

- High-Quality Materials: Use of corrosion-resistant alloys such as stainless steel, Hastelloy, or duplex stainless steel to handle aggressive chemicals and abrasive solids.

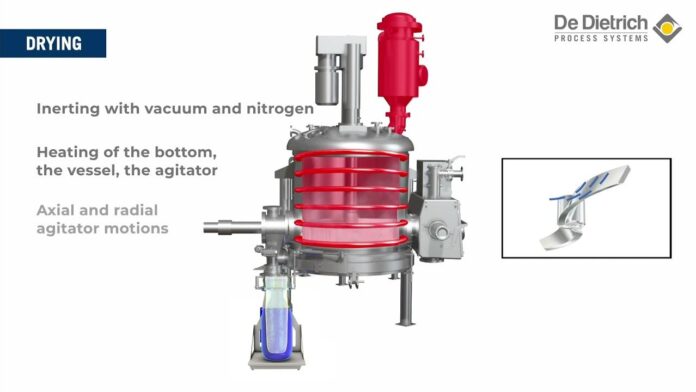

- Agitator Design: Customizable agitator types, including paddle, plow, or anchor, to ensure uniform cake formation and efficient washing.

- Vacuum and Pressure Control: Precise management of vacuum and pressure conditions to optimize filtration and drying cycles.

- Automation and Monitoring: Integration of sensors, PLCs, and HMIs for real-time process control and data logging.

- CIP/SIP Compatibility: Clean-in-place and steam-in-place features for efficient cleaning, sterilization, and regulatory compliance.

- Safety Features: Mechanical seals, interlocks, pressure relief devices, and inerting systems to minimize operational hazards.

Considerations When Choosing a Manufacturer

When selecting a global ANFD supplier, manufacturers should consider factors such as product quality, process customization, safety compliance, after-sales support, and international certifications. A reputable supplier will provide documentation for fabrication, testing, and material traceability, supporting regulatory audits and ensuring long-term reliability. Additionally, the ability to provide tailored solutions and support during installation, commissioning, and maintenance is essential for maximizing operational efficiency and minimizing downtime.

Conclusion

The global market for Agitated Nutsche Filter Dryers is diverse, with manufacturers in Europe, North America, and Asia offering innovative, high-performance solutions for various industrial applications. Leading suppliers combine advanced engineering, automation, safety features, and regulatory compliance to deliver efficient, reliable, and customizable systems. Understanding the offerings of these global manufacturers allows companies to select equipment that meets specific production requirements, ensures consistent product quality, and enhances overall process efficiency. By partnering with a reputable Agitated Nutsche Filter Dryer Manufacturer, industries can achieve optimized solid-liquid separation, efficient washing and drying, and safe, reliable operations across diverse manufacturing environments.