Distribution centers are the backbone of modern supply chains, responsible for managing large volumes of goods efficiently. In these high-demand environments, the speed and accuracy of material handling play a critical role in ensuring timely deliveries and maintaining customer satisfaction. To meet these challenges, many distribution centers are turning to advanced conveyor systems that optimize workflow and reduce manual labor. Among these, telescopic conveyors have emerged as a particularly effective solution for improving operations.

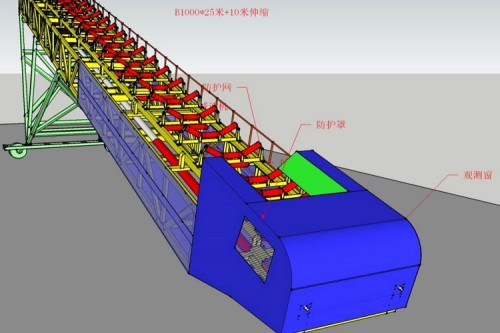

A telescopic conveyor is a flexible conveyor system that can extend and retract, allowing goods to be transferred directly into trucks, trailers, or storage areas. This adjustability ensures efficient use of space while minimizing the distance that workers need to carry packages manually. By incorporating telescopic conveyors, distribution centers can improve loading and unloading speeds, enhance workplace safety, and reduce operational costs.

Increased Loading and Unloading Efficiency

One of the primary advantages of telescopic conveyors is their ability to streamline loading and unloading processes. Traditional methods often involve workers carrying goods manually or using fixed conveyors that do not reach deep into trucks or containers. This approach can be slow and labor-intensive.

Telescopic conveyors extend directly into vehicles, allowing packages to move quickly from the warehouse floor to the truck without repeated handling. This continuous flow reduces the time trucks spend at the dock, improving turnaround times and enabling distribution centers to handle higher shipment volumes efficiently.

Reduced Labor Costs and Worker Fatigue

Manual handling of packages is a significant contributor to worker fatigue and labor costs in distribution centers. Repetitive lifting and carrying can lead to physical strain, injuries, and decreased productivity over time.

By automating the movement of goods, telescopic conveyors minimize the need for employees to manually transport items across long distances. Workers can focus on tasks such as sorting, scanning, and organizing shipments rather than lifting heavy packages. This reduction in physical labor not only improves efficiency but also enhances employee safety and job satisfaction.

Space Optimization in Distribution Centers

Space utilization is a critical concern in distribution centers where every square foot counts. Fixed conveyor systems often occupy large areas of the dock, limiting flexibility and movement.

Telescopic conveyors offer a compact design that retracts when not in use, freeing up valuable floor space. This retractable feature allows distribution centers to maintain organized and clutter-free environments, improving accessibility for forklifts and other equipment while supporting a more flexible layout for varying shipment sizes and dock configurations.

Enhanced Safety and Ergonomics

Safety is a top priority in distribution centers, where heavy lifting and repetitive tasks increase the risk of injury. Telescopic conveyors reduce the need for manual handling, decreasing the likelihood of accidents caused by slips, trips, or overexertion.

Ergonomic benefits are another key advantage. By positioning the conveyor closer to workers and minimizing bending, reaching, or lifting, these systems support healthier work practices. Safer operations not only protect employees but also reduce downtime and associated costs from workplace injuries.

Versatility for Different Package Types

Distribution centers often deal with a wide variety of package sizes and shapes. Telescopic conveyors are highly versatile, capable of handling cartons, parcels, bags, and other packaged goods. Adjustable height settings and extendable sections allow the conveyor to align with different loading dock configurations and vehicle types.

This flexibility ensures consistent performance across various shipping scenarios, making telescopic conveyors suitable for e-commerce fulfillment centers, courier hubs, retail distribution facilities, and more.

Improved Operational Speed and Accuracy

The speed of distribution operations has a direct impact on delivery performance and customer satisfaction. Telescopic conveyors enable faster movement of goods, reducing delays during peak shipping periods.

Automation and continuous flow also contribute to higher accuracy in sorting and loading. Packages can be systematically placed, reducing the risk of errors and damage during handling. Improved accuracy ensures that shipments reach their destinations intact and on time, enhancing service quality and reliability.

Cost-Effective Long-Term Investment

Although telescopic conveyors require an initial investment, the long-term benefits often outweigh the upfront cost. By increasing efficiency, reducing labor needs, and minimizing workplace injuries, these systems contribute to lower operational expenses over time.

Additionally, the reduced handling and faster loading times allow distribution centers to process more shipments without increasing staff levels. This scalability ensures that the investment continues to deliver value as business operations grow.

Conclusion

Telescopic conveyors offer significant advantages for distribution centers, including faster loading and unloading, reduced labor costs, optimized space, enhanced safety, and improved operational accuracy. Their flexibility and adaptability make them ideal for modern logistics environments where efficiency and reliability are crucial.

By incorporating telescopic conveyors into warehouse operations, distribution centers can streamline material handling, boost productivity, and support sustainable growth. As logistics demands continue to increase, these systems provide a practical and cost-effective solution for efficient and safe distribution processes.