Sheet metal fabrication is a critical process in numerous industries, including automotive, aerospace, construction, and electronics. The ability to cut, shape, and form metal sheets efficiently and precisely is essential for producing high-quality components. Among the tools that have revolutionized this field, power punch machines stand out for their speed, versatility, and accuracy. These machines have become indispensable in modern sheet metal fabrication, providing solutions for both simple and complex operations.

Enhancing Efficiency in Metal Cutting and Shaping

Power punch machines streamline the process of creating holes, slots, and intricate patterns in sheet metal. Unlike manual methods, which are time-consuming and prone to error, these machines can perform repetitive tasks rapidly and with consistent precision. Many Power Punch Machine systems include automated feeding and positioning mechanisms, allowing operators to process multiple sheets continuously. This automation significantly reduces cycle time, increases throughput, and allows manufacturers to meet tight production schedules while maintaining high-quality standards.

Precision and Consistency in Fabrication

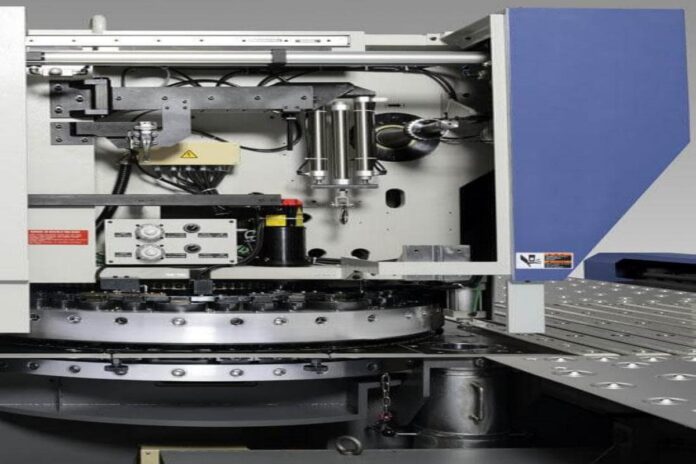

One of the primary roles of power punch machines in sheet metal fabrication is ensuring precision. The machines are designed to maintain tight tolerances across thousands of cycles, which is critical for components that must fit together perfectly. Consistency reduces material waste, lowers the risk of defective parts, and ensures reliable assembly of finished products. Modern machines often incorporate CNC technology, programmable logic controllers, and sensors that allow operators to program complex punching patterns and maintain consistent results regardless of production volume.

Versatility Across Materials and Thicknesses

Power punch machines are capable of handling a wide variety of metals, including steel, aluminum, copper, and alloys, as well as different sheet thicknesses. Adjustable punch force, die selection, and stroke settings allow the machine to adapt to the properties of the material being processed. Softer metals like aluminum can be punched quickly without excessive force, while harder metals such as stainless steel require higher pressure and slower operation. This versatility enables manufacturers to use a single machine for multiple applications, reducing equipment costs and increasing production flexibility.

Complex Patterns and Custom Designs

In addition to simple holes and slots, power punch machines are capable of producing complex shapes, perforations, and decorative patterns. This capability is particularly valuable in industries like electronics, HVAC, and architectural metalwork, where precision and design complexity are essential. CNC-controlled machines allow operators to create intricate designs with minimal setup time and high repeatability. The ability to produce custom patterns efficiently makes power punch machines a valuable asset for manufacturers catering to specialized or high-precision applications.

Multi-Layer and High-Volume Production

Power punch machines also enable multi-layer punching, which involves processing multiple sheets simultaneously. This feature is useful for high-volume production runs, as it reduces handling time and ensures uniform hole patterns across stacked sheets. Multi-layer capabilities increase production efficiency while maintaining quality and consistency, which is essential for large-scale manufacturing in automotive, appliance, and construction industries.

Integration with Automation and Industry 4.0

Modern power punch machines are increasingly integrated into automated production lines and smart factories. They can communicate with robotic feeders, conveyors, and other machinery, forming a seamless workflow that reduces human intervention and increases operational efficiency. Integration with Industry 4.0 systems allows for real-time monitoring of production data, predictive maintenance, and remote diagnostics, further enhancing machine performance and reducing downtime. This connectivity ensures that power punch machines remain central to optimized and intelligent sheet metal fabrication processes.

Reducing Waste and Improving Cost Efficiency

By maintaining precision and minimizing errors, power punch machines contribute to material savings and cost efficiency. Accurate punching reduces scrap and eliminates the need for secondary operations such as manual drilling or filing. Energy-efficient models also consume less power during operation, lowering production costs while supporting sustainable manufacturing practices. The combination of speed, accuracy, and efficiency makes power punch machines a cost-effective solution for fabricators of all sizes.

Conclusion

The Power Punch Machine plays a crucial role in modern sheet metal fabrication by enhancing speed, precision, versatility, and cost-efficiency. Its ability to process various metals, handle different thicknesses, produce complex patterns, and integrate with automated production systems has made it an indispensable tool for industries ranging from automotive to electronics. By enabling high-volume, accurate, and consistent fabrication, power punch machines continue to drive innovation and productivity in metalworking operations, solidifying their place at the heart of modern manufacturing.