A modern press machine factory is a highly organized and technologically advanced facility where power press machines are designed, manufactured, and assembled to meet the precise requirements of various industries. These machines are crucial in metal forming, cutting, and shaping operations, and the workflow in the factory ensures that each press achieves maximum efficiency, accuracy, and reliability. Understanding the operations and processes within such a facility highlights the complexity and sophistication of modern manufacturing.

The workflow in a press machine factory begins with design and material planning. Engineers develop detailed CAD models, specifying dimensions, tolerances, and materials for every component of the press machine. Raw materials are then selected based on strength, durability, and suitability for high-force operations. Within a Press Machine Factory, these materials are carefully processed, including cutting, shaping, and heat-treating, to prepare them for precise machining. Advanced tracking and inventory management systems ensure that all required materials are available and meet quality standards before production begins.

Component Machining and Precision

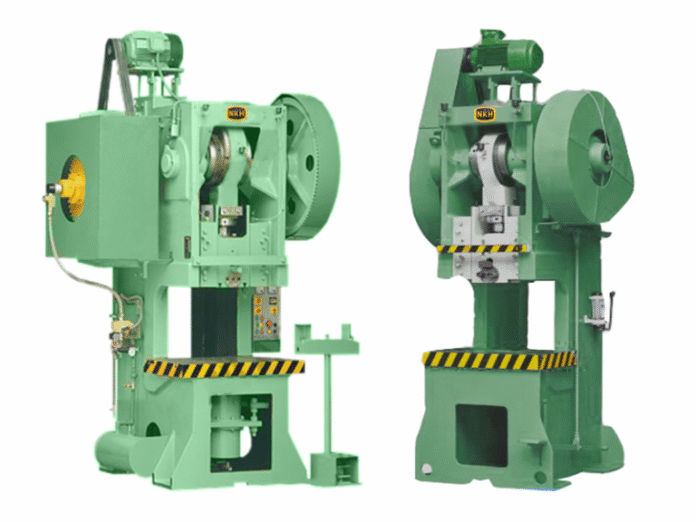

Once materials are prepared, the workflow moves to component machining. CNC machines, lathes, milling machines, and laser cutters are used to produce critical parts such as frames, rams, slides, gears, and hydraulic cylinders. Precision is key in this stage, as even minor deviations can affect the machine’s performance. Coordinate measuring machines (CMMs) and other precision instruments are used to verify dimensions and surface finishes, ensuring that components adhere to strict tolerances. Proper machining lays the foundation for smooth assembly and reliable operation.

Assembly Line Operations

After machining, components are transferred to the assembly section, where structured workflows ensure accuracy and efficiency. Frames, rams, slides, and dies are aligned using specialized jigs and fixtures to maintain structural integrity. Bolts and fasteners are torqued to precise specifications, and moving components are lubricated to reduce friction and wear. Assembly operations are carefully sequenced to minimize handling errors and ensure that every press machine meets design requirements.

Electrical and automation systems are integrated during assembly. Programmable logic controllers (PLCs), sensors, servo drives, and human-machine interfaces (HMIs) are installed and calibrated. Automated feeding systems and robotic tools are often included to improve efficiency and reduce manual labor. These integrated systems allow modern press machines to perform complex operations, such as variable stroke patterns and adaptive forming, with high precision and reliability.

Quality Control and Testing

Quality control is embedded at multiple stages of the workflow. Components are inspected for material integrity, dimensional accuracy, and surface finish before assembly. During assembly, alignment, lubrication, and mechanical movement are checked, and after the press is fully assembled, functional testing is conducted. Machines are tested under simulated operational conditions to verify stroke accuracy, force application, cycle speed, and repeatability. Safety systems, including emergency stops, light curtains, and interlocks, are also tested to ensure compliance with industrial safety standards.

Calibration and Performance Verification

Calibration is a critical part of workflow operations in a modern press machine factory. After functional testing, machines are fine-tuned using calibration tools and sensors. Load testing, stroke measurement, and performance monitoring ensure that the press delivers consistent force and precise operation. Long-term durability tests may also be conducted to simulate extended use and identify potential weaknesses. This stage guarantees that the machine is ready for industrial applications immediately upon delivery.

Automation and Digital Integration

Modern press machine factories rely heavily on automation and digital integration to optimize workflow. Material handling, component placement, and assembly are often supported by robotic systems. Digital monitoring tools track production progress, identify bottlenecks, and provide real-time feedback on machine performance. These technologies help reduce errors, improve throughput, and maintain consistent quality across multiple production runs. Automation also allows skilled personnel to focus on complex tasks such as quality analysis and process improvement rather than repetitive labor.

Workforce and Operational Efficiency

While technology is central to modern operations, the workforce remains critical in maintaining efficiency. Technicians, engineers, and operators are trained to handle advanced machinery, perform inspections, and troubleshoot any issues during production. Continuous training programs ensure that staff are up-to-date with the latest equipment, safety protocols, and best practices. A well-trained workforce, combined with automated systems, maximizes operational efficiency and reduces downtime in the factory.

Conclusion

The workflow and operations in a modern press machine factory combine advanced technology, precise machining, structured assembly, and rigorous quality control to produce high-performance power press machines. From material preparation to calibration and testing, each stage is carefully managed to ensure precision, reliability, and efficiency. By integrating automation, digital monitoring, and skilled labor, these factories are able to deliver machines that meet the complex demands of modern manufacturing industries. This organized and technologically advanced approach ensures that press machines maintain high quality and consistency, supporting industrial productivity and growth.