Maintaining consistent product quality is a fundamental requirement in modern manufacturing. From chemical production to food and beverage processing, and pharmaceutical manufacturing, accurate monitoring of chemical parameters ensures that products meet specifications and regulatory standards. Among these parameters, pH plays a critical role, influencing reaction efficiency, product stability, and overall quality.

A dependable pH sensor is an essential tool in manufacturing quality control. By providing precise, real-time measurements of acidity and alkalinity, pH sensors help operators maintain optimal conditions throughout the production process. Their integration into quality control systems supports consistent product characteristics, reduces waste, and ensures compliance with safety and regulatory requirements.

The Importance of pH in Manufacturing Processes

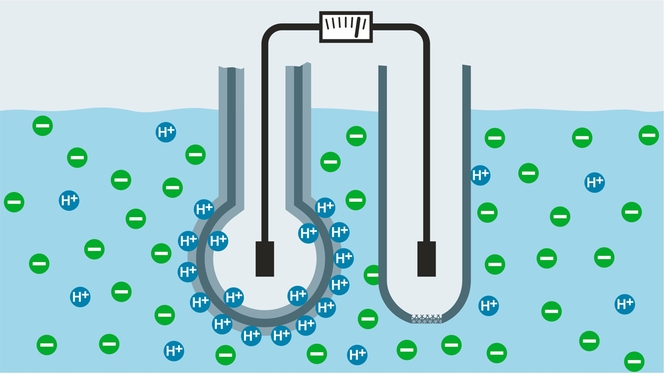

pH is a measure of hydrogen ion concentration in a solution and affects chemical reactions, solubility, and product stability. In industries like chemical manufacturing, a deviation in pH can alter reaction rates and reduce product yield. In food and beverage production, pH affects flavor, texture, and microbial safety, while in pharmaceuticals, it influences drug stability and bioavailability.

Accurate pH monitoring allows manufacturers to maintain controlled production conditions, ensuring that every batch meets the desired specifications. Even minor fluctuations in pH can result in defects, making precise measurement a key component of quality control.

Real-Time Monitoring for Process Consistency

Traditional quality control methods often rely on periodic sampling and laboratory testing, which can miss sudden pH changes. Digital and online pH sensors provide continuous, real-time data, enabling immediate detection of deviations. This allows operators to take corrective action before defective products are produced.

By integrating sensors into automated systems, manufacturers can maintain stable process conditions and improve consistency across batches. Real-time monitoring reduces variability, supports standardized production, and ensures that finished products meet quality expectations.

Supporting Regulatory Compliance

Manufacturers are often subject to strict regulatory standards, especially in pharmaceuticals, food and beverage, and chemical industries. Maintaining proper pH levels is critical for safety, efficacy, and environmental compliance. Accurate pH data is frequently required for documentation, audits, and reporting to regulatory authorities.

pH sensors provide reliable, traceable measurements that support compliance with quality and safety regulations. The ability to record and log data continuously ensures that manufacturers can demonstrate adherence to standards at all times.

Enhancing Product Safety and Stability

In many industries, pH directly affects product safety. Acidic or alkaline conditions outside the recommended range can promote microbial growth, chemical degradation, or corrosion of containers and equipment. Monitoring pH helps prevent these risks by ensuring that products remain within safe limits throughout production and storage.

This is particularly important in pharmaceuticals and food processing, where precise pH control preserves the integrity of the product and protects consumers. A pH sensor provides the timely feedback necessary to maintain these safety standards consistently.

Optimizing Production Efficiency

In addition to quality control, pH monitoring can improve overall production efficiency. Maintaining optimal pH conditions ensures that chemical reactions proceed as intended, minimizing waste and maximizing yield. For food and beverage manufacturers, consistent pH reduces the need for reprocessing or product rejection.

Integration with automated process control systems allows operators to adjust chemical dosing, temperature, and other variables in response to pH data. This automation reduces manual intervention, minimizes errors, and enhances overall operational efficiency.

Long-Term Benefits of pH Monitoring

Investing in reliable pH sensors offers long-term benefits beyond immediate quality control. Continuous monitoring supports process optimization, reduces material waste, extends equipment lifespan, and enhances regulatory compliance. Data collected over time can be used for trend analysis, process improvement, and preventive maintenance planning.

By ensuring accurate, consistent pH measurement, manufacturers can maintain high standards of quality while improving productivity and reducing costs.

Conclusion

A pH sensor is a vital tool for enhancing quality control in manufacturing. By providing accurate, real-time measurements, these sensors ensure product consistency, safety, and compliance with regulatory standards. Their integration into automated systems allows manufacturers to monitor production conditions continuously, take corrective actions promptly, and optimize processes. The result is improved product quality, reduced waste, and increased operational efficiency, making pH monitoring an essential component of modern manufacturing practices.