Farm equipment is the backbone of agricultural productivity. From plowing to harvesting, these machines endure countless hours of hard labor in tough environmental conditions. Among the many components that keep them running smoothly, engine mounts play a critical yet often underappreciated role. These mounts support the engine, isolate vibrations, and ensure the machinery remains stable during operation.

Despite their importance, engine mounts are frequently overlooked during routine maintenance. Regular inspection of these parts can prevent significant mechanical issues, reduce downtime, and extend the lifespan of farm equipment. Knowing when and how to inspect engine mounts can save farmers time, money, and unnecessary stress during busy agricultural seasons.

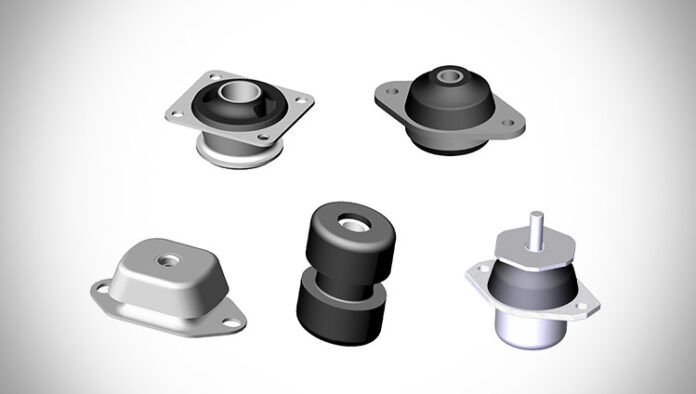

Farmers and agricultural maintenance teams looking to ensure reliability and durability in their machines can find high-quality engine mounts designed specifically for farm equipment. Choosing the right replacement parts from trusted suppliers is essential to maintaining optimal engine performance and reducing long-term wear and tear.

Why Engine Mounts Matter in Farm Equipment

Engine mounts are designed to hold the engine securely in place and absorb the vibrations produced during operation. In farm equipment, this is particularly important due to the constant exposure to rough terrain, uneven loads, and demanding work schedules.

When an engine mount is functioning properly, it:

- Maintains correct engine alignment

- Minimizes vibration transfer to the chassis and operator’s cabin

- Protects sensitive components like hoses, belts, and electrical wiring

- Reduces wear on engine and transmission joints

Worn or damaged mounts, on the other hand, can cause excessive engine movement, misalignment, and stress on surrounding parts, leading to performance issues and costly repairs.

Common Signs of Failing Engine Mounts

Engine mounts are subject to stress every time the machine operates. Over time, even the most durable mounts degrade. Identifying the early signs of wear can prevent bigger issues down the road.

Here are some symptoms to watch for:

- Increased vibration: More noticeable shaking during engine operation often indicates that the rubber in the mount is deteriorating.

- Clunking or banging noises: These sounds may occur when accelerating or shifting gears, suggesting the engine is moving excessively within its bay.

- Misalignment: If belts or pulleys appear out of place or the engine seems tilted, the mounts could be failing.

- Visible damage: Cracks, corrosion, or sagging in the mount structure during visual inspection are strong signs that a replacement is needed.

If any of these symptoms appear, it’s important to conduct a detailed inspection immediately.

How to Inspect Engine Mounts

Regular inspections should be a part of every farm equipment maintenance routine. Here’s a simple guide on how to inspect engine mounts safely and effectively:

- Ensure the engine is cool and powered off before inspection to avoid injury.

- Visually check the mounts for signs of wear, such as cracks, splits, or oil saturation that could degrade the rubber.

- Look for engine movement by gently pushing the engine. Excessive movement may indicate a broken or weak mount.

- Listen for noises during operation that may suggest loose or damaged mounts.

- Check for alignment issues in belts, hoses, and pulleys. Misalignment may be the result of engine shifting due to faulty mounts.

If inspection reveals any concerns, replacing the mounts is essential to prevent further complications.

Benefits of Routine Engine Mount Inspections

Incorporating regular mount checks into your maintenance schedule offers several advantages:

- Reduces mechanical failures: Preventive maintenance helps identify problems early, reducing the chance of costly repairs or equipment failure during critical work periods.

- Extends equipment lifespan: Keeping engine mounts in good condition preserves other parts of the machine by reducing stress and vibration damage.

- Improves operator comfort: Vibrations from failing mounts can travel to the cabin, causing discomfort and fatigue for the operator.

- Enhances safety: Secure engines are less likely to cause accidents or damage during operation.

When to Replace Engine Mounts

There’s no universal timeline for engine mount replacement, as it depends on usage, operating conditions, and machine type. However, it’s a good practice to inspect mounts during every major service and replace them if:

- The rubber appears cracked or worn

- The metal components show rust or damage

- The engine is visibly misaligned

- Noise and vibration levels have increased

Replacing worn-out mounts before they fail can prevent more serious and expensive issues.

Conclusion

The condition of your engine mounts has a direct impact on the performance, efficiency, and safety of your farm equipment. Regular inspections are essential for identifying early signs of wear, preventing equipment breakdown, and extending the life of your machinery.

Don’t wait until there’s a noticeable problem. Proactive maintenance, including inspecting and replacing engine mounts as needed, will keep your equipment running at peak performance and reduce unexpected downtime during critical farming operations. Making engine mount checks a priority is a small step that yields long-term benefits in both reliability and cost savings.