In today’s rapidly evolving manufacturing landscape, custom plastic fabrication has emerged as a game-changer for businesses seeking innovative, durable, and cost-effective solutions. Whether you need specialized components for automotive, medical devices, electronics, or retail displays, the flexibility and versatility of custom plastic fabrication make it an indispensable service. This article explores the fundamentals, benefits, applications, and future trends of custom plastic fabrication, providing insights for businesses and individuals looking to harness its full potential.

What is Custom Plastic Fabrication?

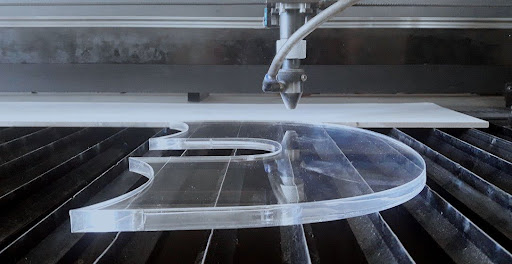

Custom plastic fabrication refers to the process of designing, engineering, and producing plastic parts or products tailored to unique specifications. Unlike mass production, which relies on standardized molds and designs, custom fabrication leverages advanced techniques—such as CNC machining, vacuum forming, injection molding, and 3D printing—to create bespoke plastic solutions.This tailored approach allows for the creation of prototypes, one-off products, or large-scale production runs, all designed to meet specific functional, mechanical, and aesthetic requirements.

Benefits of Custom Plastic Fabrication

1. Design Flexibility

One of the most significant advantages of custom plastic fabrication is the freedom it offers in design. Manufacturers can produce complex shapes, intricate details, and even incorporate branding elements directly into the parts. This flexibility makes it ideal for industries where standard solutions fall short.

2. Material Versatility

Custom plastic fabrication supports a wide array of plastic materials, including acrylic, polycarbonate, PVC, ABS, and more. Each material offers unique properties such as high impact resistance, optical clarity, chemical resistance, or flexibility, ensuring that every project can be optimized for its intended use.

3. Cost-Effectiveness

For low to medium production volumes, custom plastic fabrication can be a more economical choice compared to traditional metalwork or off-the-shelf solutions. The reduction in tooling costs and the ability to iterate designs quickly contribute to overall cost savings.

4. Rapid Prototyping and Production

Modern fabrication techniques enable rapid turnaround times, allowing businesses to bring new products to market faster. Prototyping is particularly efficient, helping designers test ideas and make improvements before committing to full-scale production.

5. Durability and Quality

Plastics are inherently resistant to corrosion, moisture, and many chemicals, making them ideal for challenging environments. With precise fabrication methods, the final products boast high durability and consistent quality.

Common Applications of Custom Plastic Fabrication

Custom plastic fabrication serves a diverse range of industries, including:

Automotive: Custom dashboards, housings, and under-the-hood components.

Medical Devices: Sterile enclosures, instrument panels, and ergonomic handles.

Retail & Display: Point-of-purchase displays, signage, and protective barriers.

Electronics: Housings, panels, and insulation components.

Food & Beverage: Hygienic trays, dispensers, and processing equipment parts.

The adaptability of custom plastic fabrication ensures that no matter the industry, there is a solution tailored perfectly to each unique requirement.

The Custom Plastic Fabrication Process

The process typically involves several key stages:

Consultation & Design: Understanding the client’s needs, function, and environment for the part.

Material Selection: Choosing the best plastic material for the project’s requirements.

Prototyping: Creating a prototype using 3D printing or CNC machining for initial testing.

Fabrication: Using the chosen technique—vacuum forming, injection molding, or others—to produce the final parts.

Finishing: Polishing, painting, or assembling components as needed.

Attention to detail at each step ensures the finished product matches the client’s vision and performs as intended.

Choosing the Right Partner for Custom Plastic Fabrication

Selecting an experienced provider for custom plastic fabrication is crucial. Look for companies with:

- A proven track record in your industry.

- Access to advanced fabrication technologies.

- Skilled designers and engineers.

- A collaborative approach to project management.

A reliable partner will guide you through material selection, design optimization, and production, ensuring the highest quality results.

Future Trends in Custom Plastic Fabrication

As technology continues to advance, so too does the field of custom plastic fabrication. Some emerging trends include:

Sustainable Materials: Increasing use of recycled and biodegradable plastics to reduce environmental impact.

Smart Plastics: Integration of sensors, LEDs, or electronic components into fabricated parts.

Automation: Greater use of robotics and AI to streamline production and improve precision.

Customization at Scale: On-demand manufacturing and mass customization are becoming more accessible, enabling even small businesses to benefit from tailored solutions.

Staying ahead of these trends allows businesses to capitalize on new opportunities and remain competitive in their markets.

Conclusion

Custom plastic fabrication is reshaping the way products are designed and manufactured across a multitude of industries. With unparalleled design freedom, material versatility, and rapid production capabilities, it empowers businesses to innovate and adapt quickly. By understanding the benefits and applications of this modern manufacturing method, you can make informed decisions that drive efficiency, quality, and growth for your company.If you’re ready to explore the possibilities that custom plastic fabrication can offer your business, reach out to an experienced provider and discover how tailored solutions can bring your ideas to life.